ValveWorx

Our ValveWorx line offers customizable, reliable valve train solutions for oil and gas, ensuring efficiency and durability.

- Home

- ValveWorx

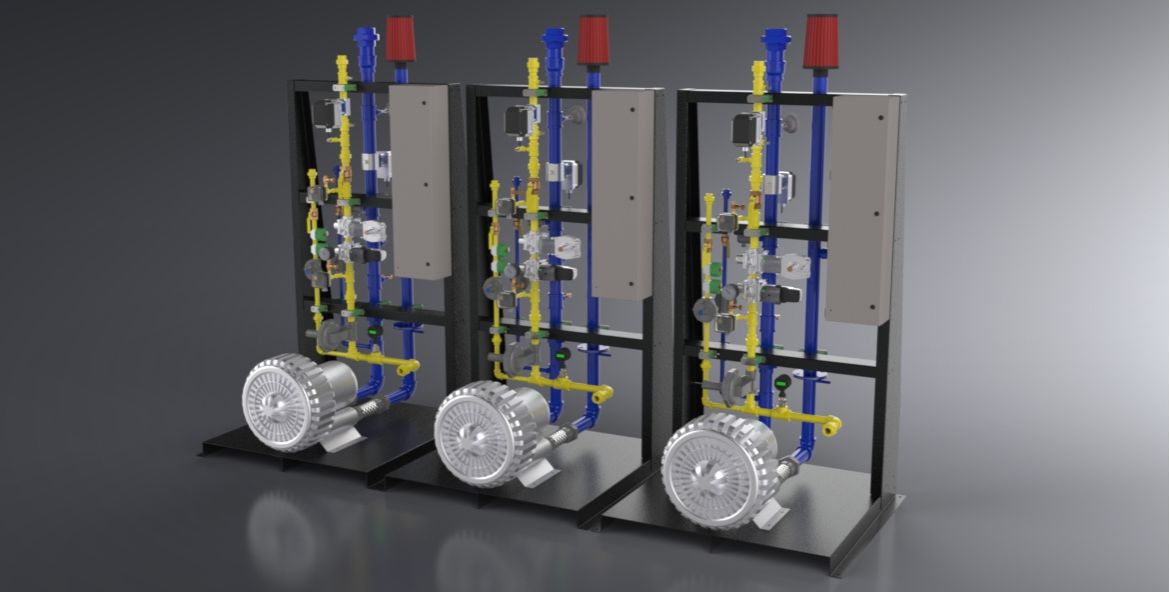

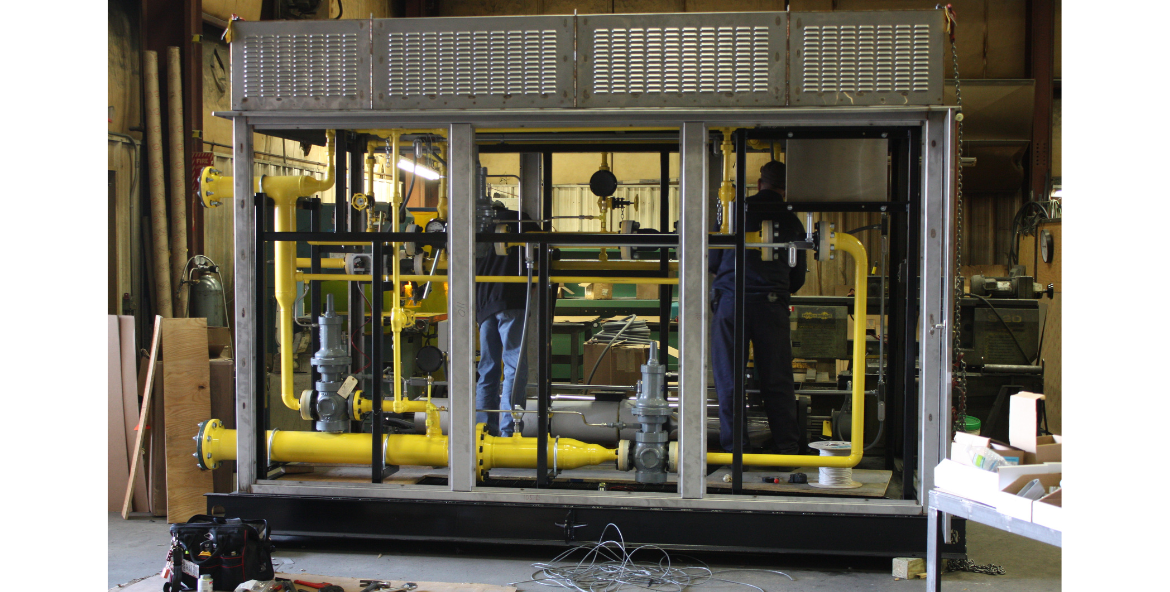

#1: Self-Contained Fuel/Air System

This compact skid allowed the owner to streamline installation by delivering the complete fuel handling and combustion air system in a single forklift drop. It includes a Main Gas Train, Pilot Train, Combustion Air Fan and Train—all integrated with a centralized Control Panel that monitors instrumentation and interfaces directly with the burner for efficient, reliable operation.

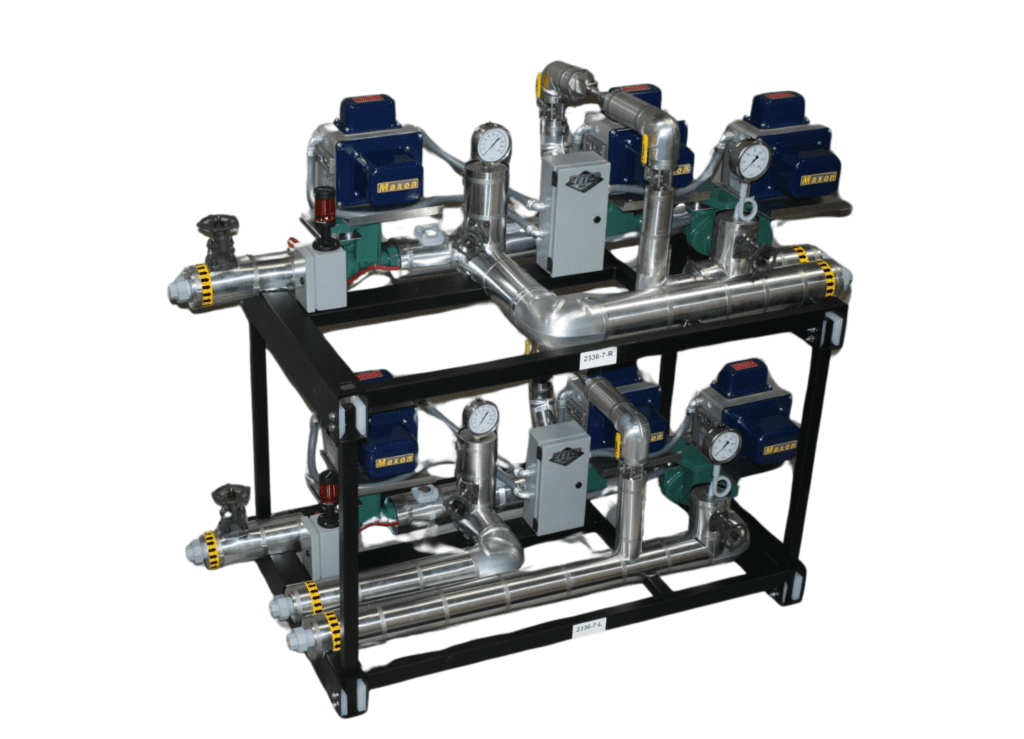

#2: Fuel Oil and Atomizing Steam Racks

ETTER supplied dozens of these integrated valve assemblies to a local power utility as part of a burner deck reconfiguration project on their power boilers. Each system delivers heavy fuel oil and atomizing steam to the burner’s oil gun, with automated purge functionality that safely clears residual oil into the furnace upon shutdown. Built to strict Utility Specifications and fully insulated at the factory, these racks offer a reliable and streamlined solution for high-performance burner operations.

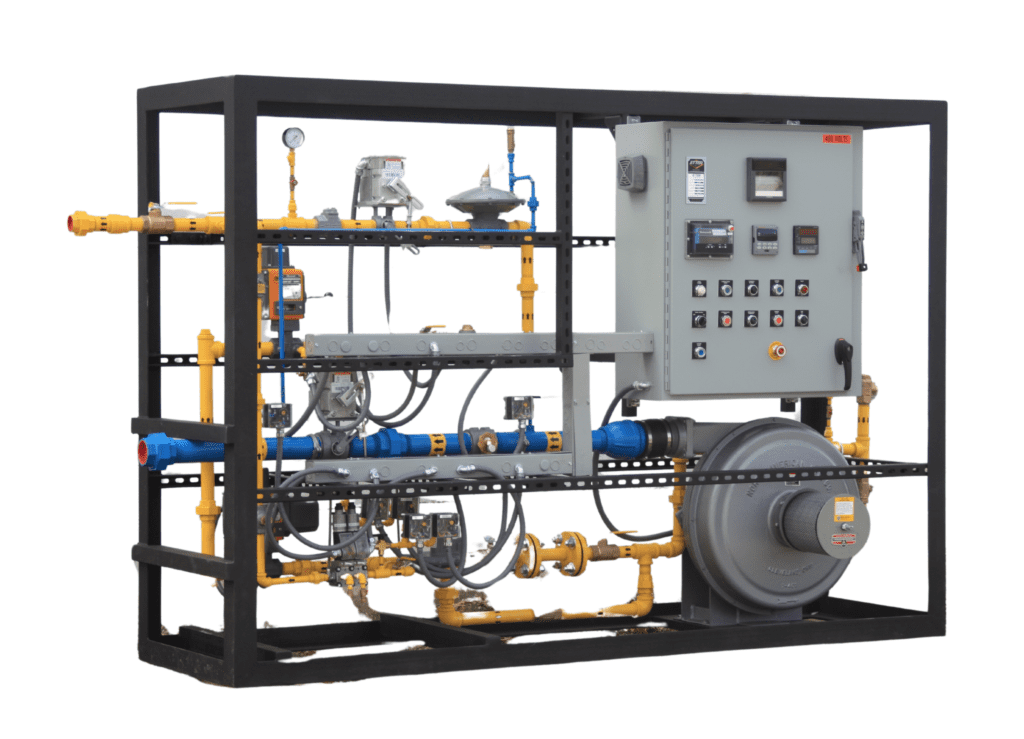

#3: Pulp & Paper RHMS

This high-pressure Regulating, Heating, and Metering Station (RHMS) was designed for a Maine-based papermill receiving 575 PSIG natural gas directly from a transmission pipeline. The system required multiple stages of pressure regulation and precise metering as a check station before delivering gas to the plant’s lime kiln. To prevent freezing caused by significant pressure drops—resulting in temperature drops of 35–40°F—the gas was reheated to protect regulators, valves, and instrumentation, ensuring safe and reliable operation.

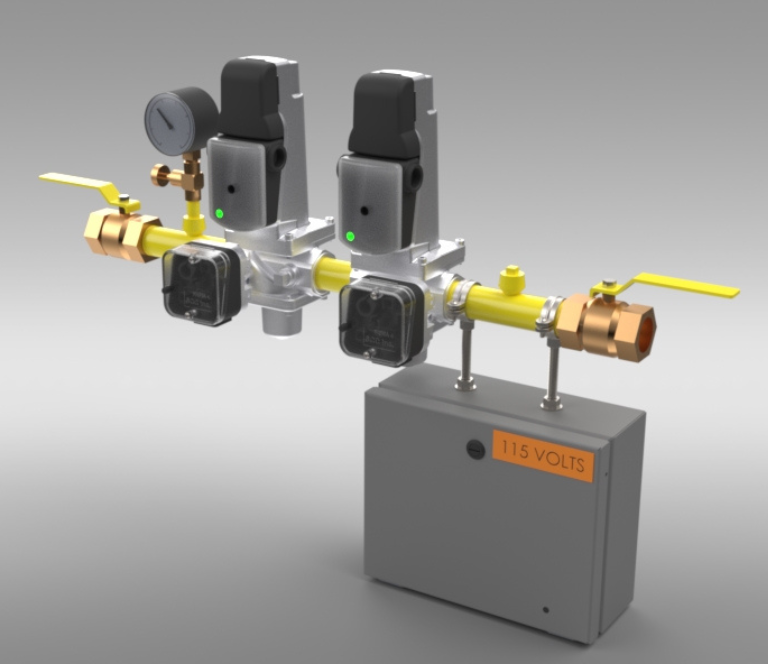

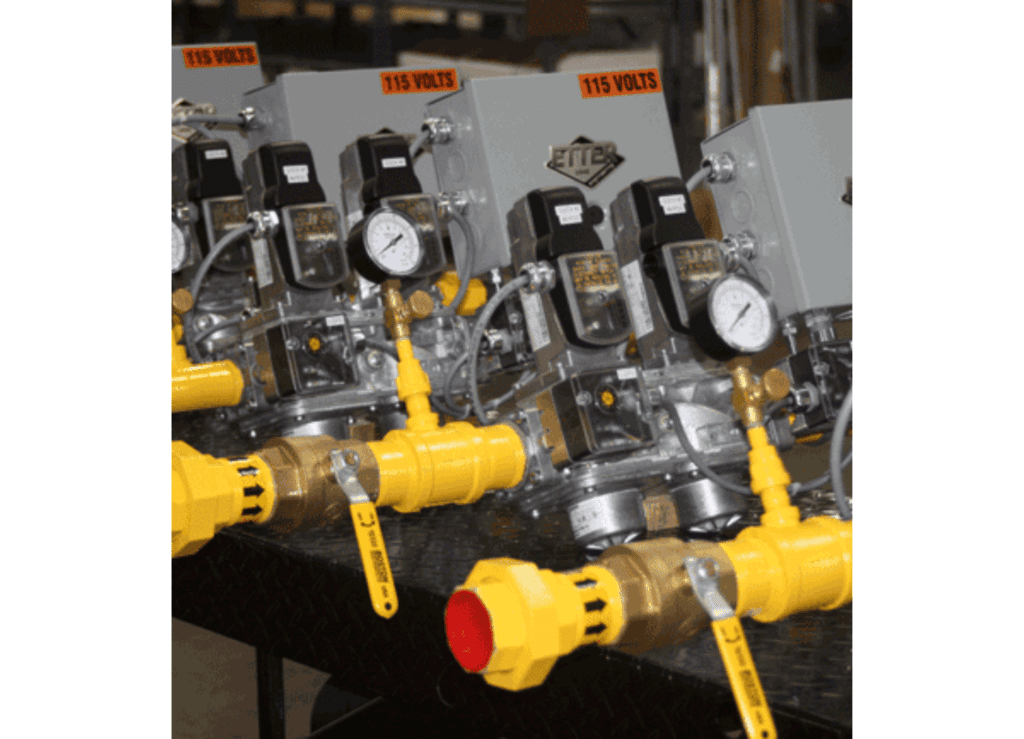

#4: Appliance-Style Valve Trains

A staple in our shop, these compact valve trains are built for a wide range of applications—from small coffee roasters to industrial salt baths. With sizes ranging from ½” to 6″ piping, ETTER delivers complete, pre-assembled systems tailored to your needs. Many OEMs in the gas combustion industry rely on us to supply turnkey valve trains, allowing them to focus on their core products instead of sourcing and assembling components. Let ETTER be an extension of your shop—with fully functional, pressure-tested systems delivered ready for installation.

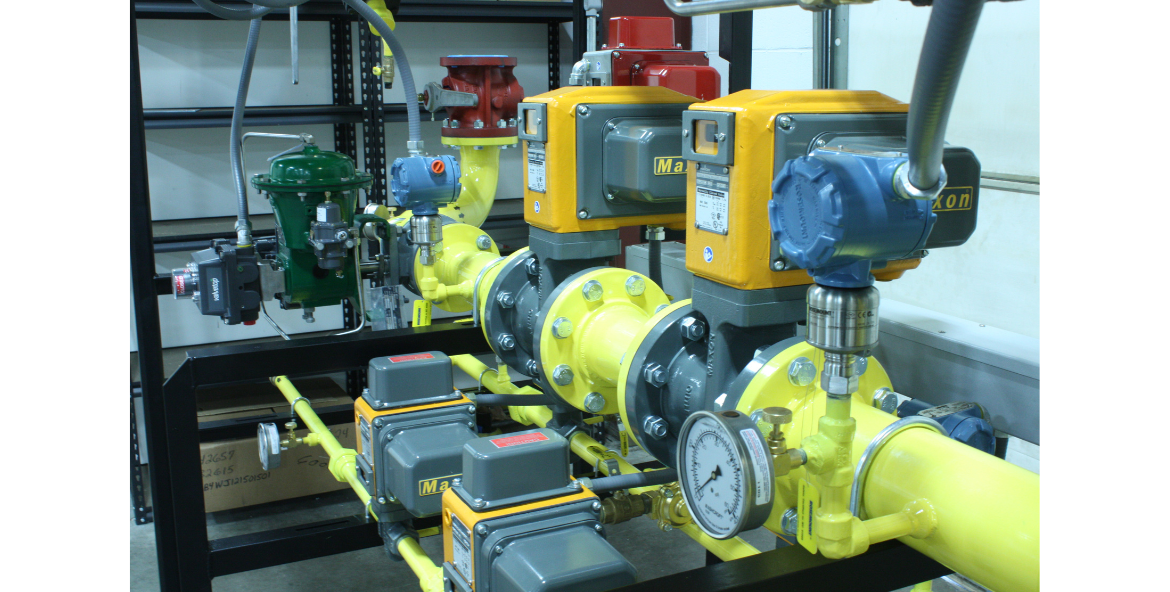

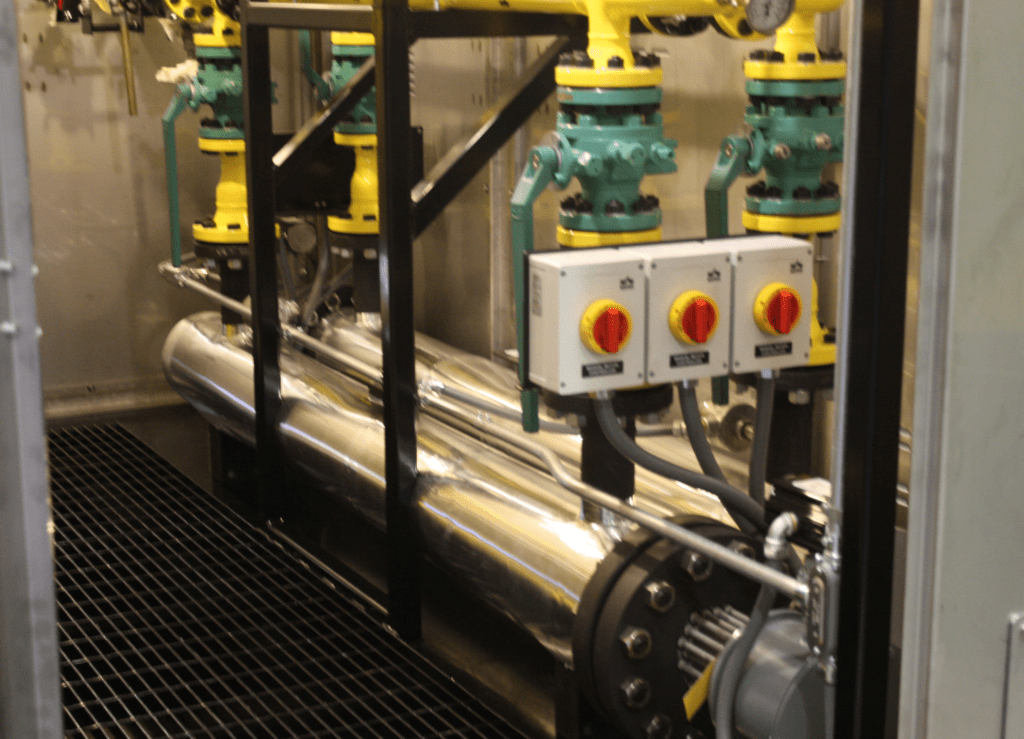

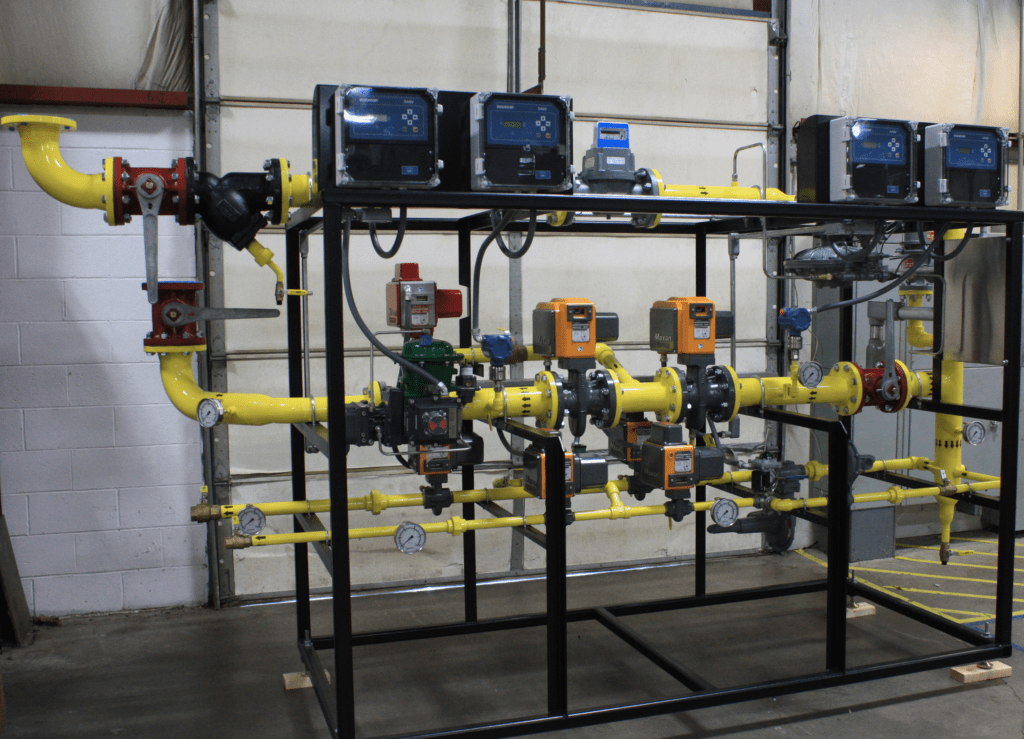

#5: Paper Mill Burner Valve Rack

Designed for an 80 MMBTUH burner in a pulp and paper facility, this system included a Main Gas Train, Starter Gas Train, and Pilot Gas Train to ensure precise burner turn-down and control. Built to demanding “Mill Grade” specifications, it features a utility-grade turbine meter, pneumatic flow control valve, high-pressure (40 PSIG) safety shut-off valves, smart pressure and temperature transmitters, and rack-mounted recorders. The result is a robust, high-accuracy system that delivers consistent performance to meet the stringent requirements of the mill.

#6: WWTP Valve Rack

Engineered for the harsh conditions of a Wastewater Treatment Plant, this valve rack is built with rugged durability in mind. It supplies a high-pressure burner on the processing line, delivering precise control and reliable performance. Designed to withstand demanding environments, it’s built to last—like a brickhouse.

Download Brochure

Download our one-sheet for detailed specs and a closer look at the ValveWorx product family and services.

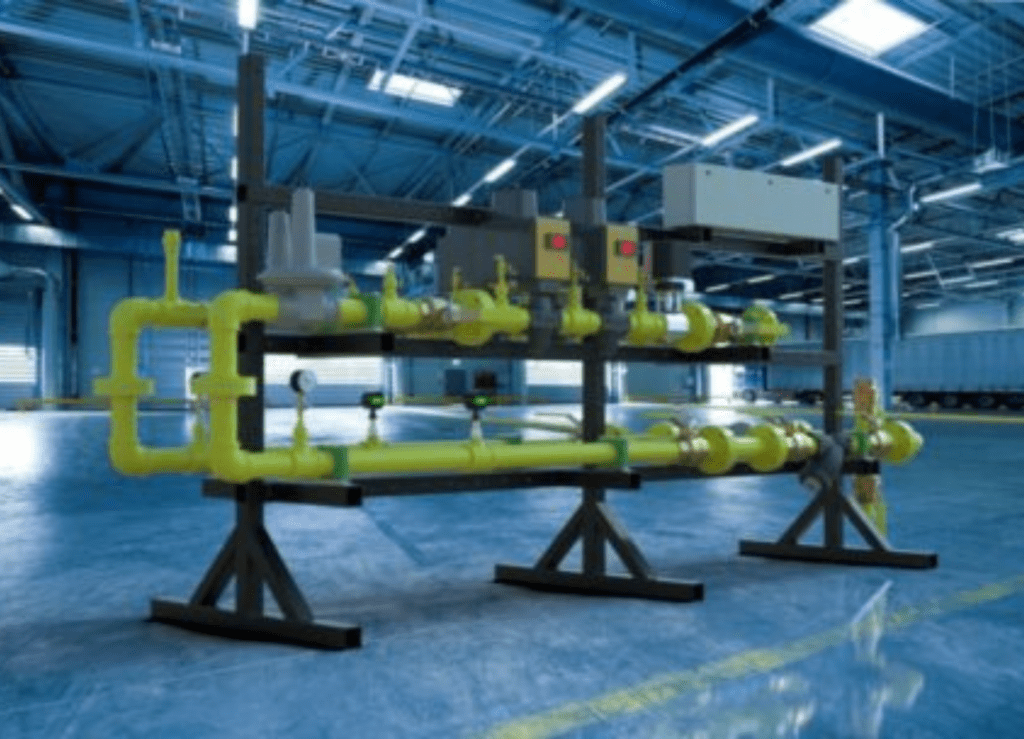

ValveWorx: High-Performance Valve Trains for Industrial Applications

With over 85 years of experience in industrial process heating and combustion, ETTER Engineering is your trusted partner for reliable valve train solutions. Our standard valve train systems are designed to deliver peak efficiency, ease of selection, and fast production times, offering the right equipment at the right price.

ETTER’s ValveWorx line features complete valve trains, pilot valve trains, and valve train modules for both oil and gas applications, built to meet NFPA-85 or NFPA-86 standards. We can also customize systems by integrating flow, meter, and regulator modules to meet your unique specifications. Using components from leading manufacturers like SIEMENS, Kromschroder, Maxon, Honeywell, and Antunes, we ensure your valve train performs at its best.

Get the right valve train solution for your process, with expert design and trusted components that ensure long-lasting reliability.

MAKING INDUSTRIAL SYSTEMS

Run smoother, safer,

and better

Our team of expert engineers are ready to provide the precision and reliability your operations deserve. Contact us today for a quote on your next project.