[Banff, Alberta | April 18,2024 ] – ETTER Engineering is proud to announce remarkable results of the Spring 2024 field testing trials conducted by the Saskatchewan Research Council (SRC) on the ETTER/Metan Group CMAS V2 unit, presented at the PTAC Methane Leadership Summit by Tyler Homan, VP of Production at TEINE Energy. The findings showcased a staggering Destruction Efficiency (DE) of 99.7% in methane reduction, surpassing expectations and rivaling that of combustors, all at a significantly lower cost of equipment and installation.

The high DE was partially attributed to the rich gas coming off their Viking Field well and expectations of 95% plus DE at less rich sites. This 95% DE leads to a 91% reduction in Green House Gas Warming Potential! This testing unequivocally affirms the CMAS unit’s capability to mitigate methane emissions in the Oil and Gas sector.

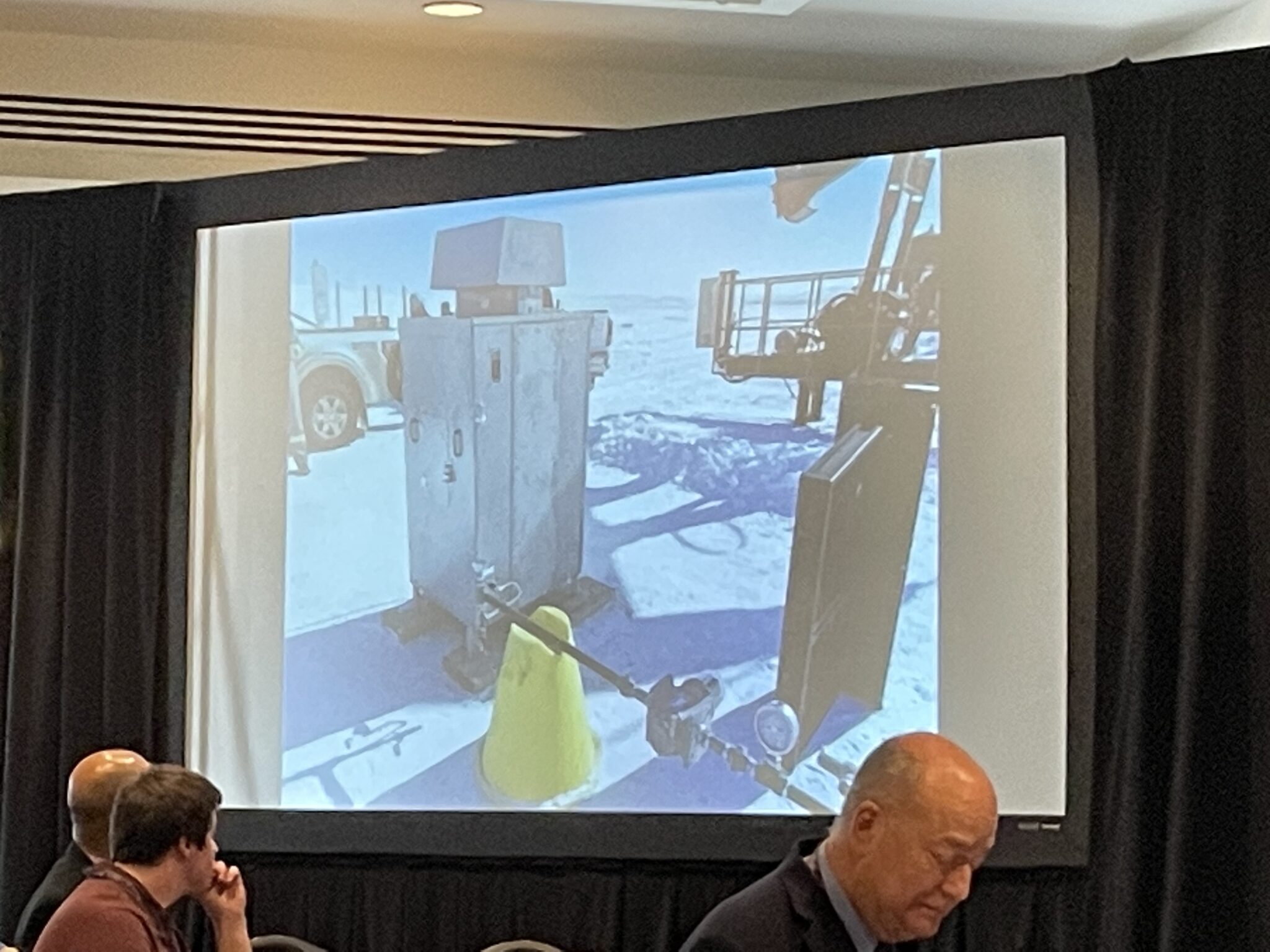

Tyler Homan highlighted the CMAS technology‘s versatility, citing its suitability for low flow ranges of 25-50 cubic meters/day. He emphasized its user-friendly deployment and maintenance, requiring minimal operator intervention while effectively initiating oxidization to drive away emissions.

Building upon feedback from TEINE Energy’s long-term tests in 2023, the 2024 CMAS V2 implementation incorporates several enhancements, with the most significant being the integration of a waste heat recovery loop. This innovation harnesses the CMAS exhausted heat from the oxidization process, offering substantial benefits. According to TEINE’s testing, the projected CO2e savings from this heating loop equate to 14 tonnes per year per CMAS unit, with estimated federal savings of $332K/year by 2025, based on a rate of $95.

This advancement underscores the economic viability of deploying CMAS technology in Oil and Gas fields and exemplifies ETTER Engineering’s commitment to continuous refinement and innovation. As we move forward, ETTER remains dedicated to advancing solutions that not only mitigate environmental impact but also drive economic prosperity in the energy sector.

Watch our video on The CMAS Solution: Reducing Greenhouse Gas Emissions

The Catalytic Methane Abatement System (CMAS) is an innovative technology designed to combat Greenhouse Gas emissions while optimizing energy production. In our latest video we explore its key features and benefits: Surface Casing Vents: Though individually small, SCV’s contribute substantially to methane emissions. The CMAS system effectively captures and mitigates this gas buildup and prevents leaks while minimizing environmental impact. Pneumatic Controls: By integrating the CMAS with pneumatic controls, we can again mitigate the methane emissions by turning them into water vapor and CO2. Enhanced Oil Production: The CMAS not only reduces emissions but can also enhance efficiency for oil production, providing a dual benefit for operators. We invite you to watch the video and share it with your network. Together, we can drive positive change and contribute to a more sustainable future.

For more information, please visit our website or contact us below:

Tom Etter

President, Etter Engineering

860-584-8842

tetter@etterengineering.com

Jon G. Moore

Vice President VP, Engineering

860-584-8842

jmoore@etterengineering.com