FurnaceWorx

Custom industrial heaters and furnaces for applications like powder coating, curing, and drying. Fully customized, shipped ready to install and run in hours.

- Home

- FurnaceWorx

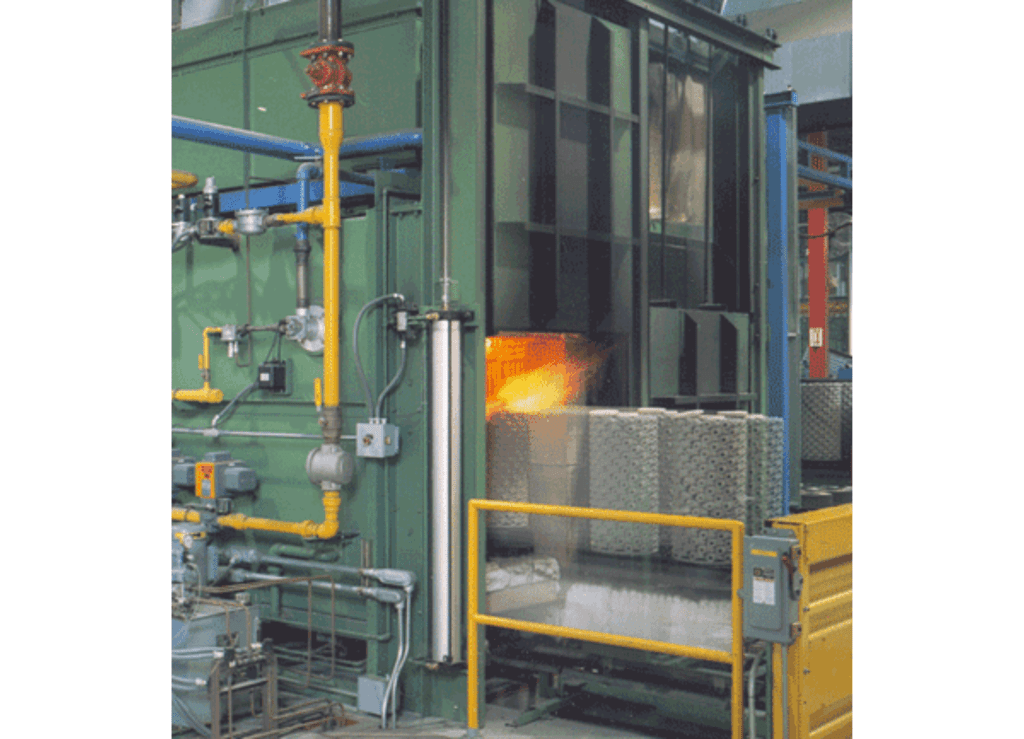

Furnace Type: Box Furnace

Typical Application: Multi-purpose Heat Treating

Project Overview: Box Furnace utilizing (6) High Velocity Burners specially designed to operate at temperatures from 600F to 2,250F meeting strict temperature uniformity requirements (+/- 10F below 1,400F, +/- 25F above 1,400F) for the aerospace industry. The uniformity is obtained by utilizing proprietary ETTER-FIRE Combustion Technology. Load Dimensions 5’ wide x 5’ deep x 4’ high.

Furnace Type: Continuous Mesh Belt

Typical Application: Billet Heater for Aluminum Forgings.

Project Overview: Furnace heated by Package-Style Burner up to 1,100F. Type 314 SS Double Balanced Weave Mesh Belt. Plug Style Circulation Fan. Belt width is 24” wide. 4’ Load Table. Heated Length is 12’ long.

Furnace Type: Investment Casting Burn-Out Furnace

Typical Application: Preheat Shells for Investment Casting.

Project Overview: Furnace utilizing (16) High Velocity Burners (3 Zones). Pulse-Fire Combustion System. Twin Pass Furnace, (15) 3’ x 3’ Pusher Cars per side operating independently per side. Heated Length is 45’ long. Includes Afterburner to eliminate residual wax smoke.

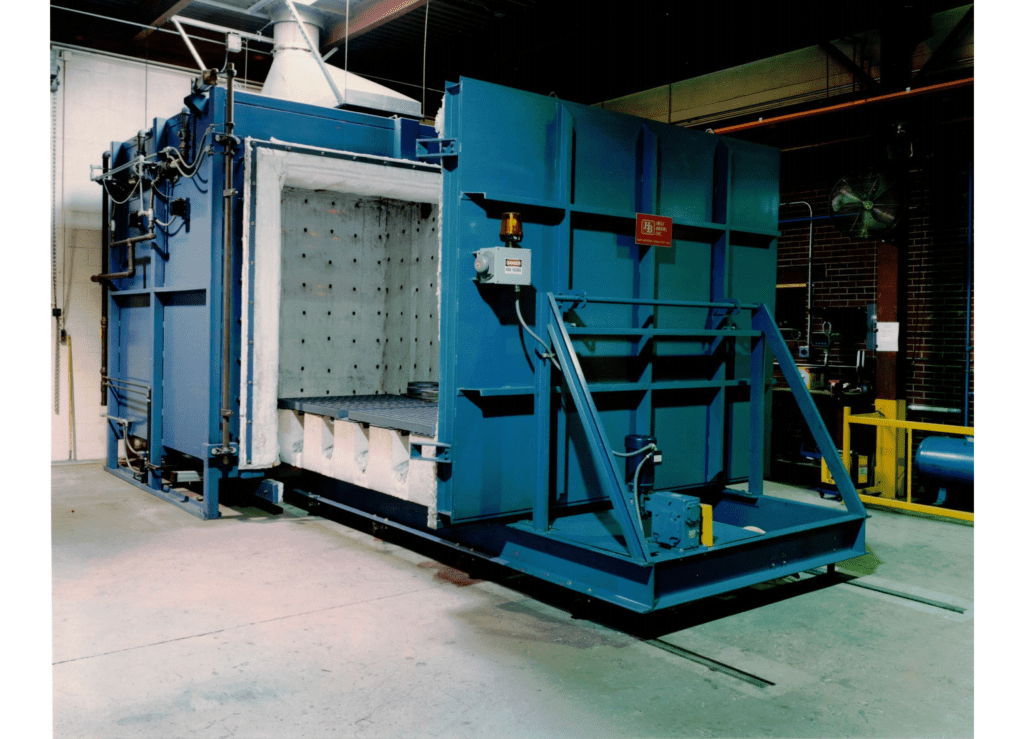

Furnace Type: Car Bottom Furnace

Typical Application: Multi-Purpose Heat Treating

Project Overview: Box Furnace utilizing (6) High Velocity Burners to operate at temperatures up to 2,000F. Standard Proportional Control. Car utilizes Fiber Swing Seal, and Pneumatic Door Closure Mechanism. Load Dimensions 6’ wide x 6’ deep x 5’ high.

Furnace Type: Box Furnace with Atmosphere Retort

Typical Application: Heat Treat Aircraft Parts

Project Overview: Box Furnace utilizing (4) High Velocity Burners to operate at temperatures up to 1,850F. Pulse-Fire Combustion System. Retort Dimensions 4’ diameter x 4’ high.

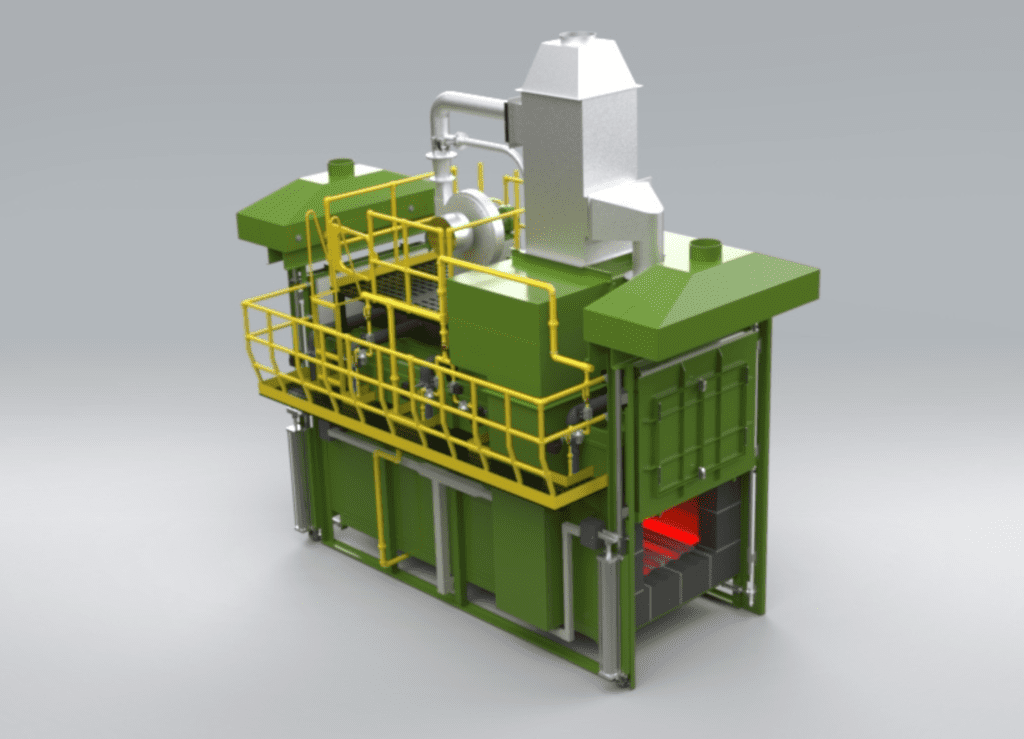

Furnace Type: Investment Casting Pusher Furnace

Typical Application: Heat treat and Curing of Investment Parts for Orthopedic replacement parts

Project Overview: Furnace utilizing (8) High Velocity Burners (3 Zones). Pulse-Fire Combustion System. Twin Pass Pusher Furnace, (12) Trays per side operating independently per side. Heated Length is 15-1/2’ long. Includes Pre-Heated Combustion Air Heat Exchanger.

Heaters & Furnaces: Custom Solutions for Industrial Heating Needs

ETTER Engineering specializes in designing and building high and low-temperature custom industrial ovens and furnaces, including heat treating furnaces, curing ovens, and powder coating lines. Whether you need gas-fired infrared, electric gas-fired infrared, forced hot air convection, or direct and indirect heating systems, ETTER has the expertise to deliver. We also excel in electric-to-gas conversions and can apply advanced gas-fired infrared technology to meet your specific drying or curing needs.

Heater & Furnace Benefits

- Fully customized to meet your product size and speed requirements

- Completely fabricated and shipped for easy installation

- Ready to run in just hours after installation

- A single source for the furnace, combustion system, and controls package

Trust ETTER’s decades of expertise to provide reliable, efficient heating solutions tailored to your unique industrial needs.

MAKING INDUSTRIAL SYSTEMS

Run smoother, safer,

and better

Our team of expert engineers are ready to provide the precision and reliability your operations deserve. Contact us today for a quote on your next project.