BurnerWorx

Our custom packaged burner systems are built to meet all required codes and incorporate the latest technology for optimal performance.

- Home

- BurnerWorx

#1: Web Driers for High Speed Cardboard Printing

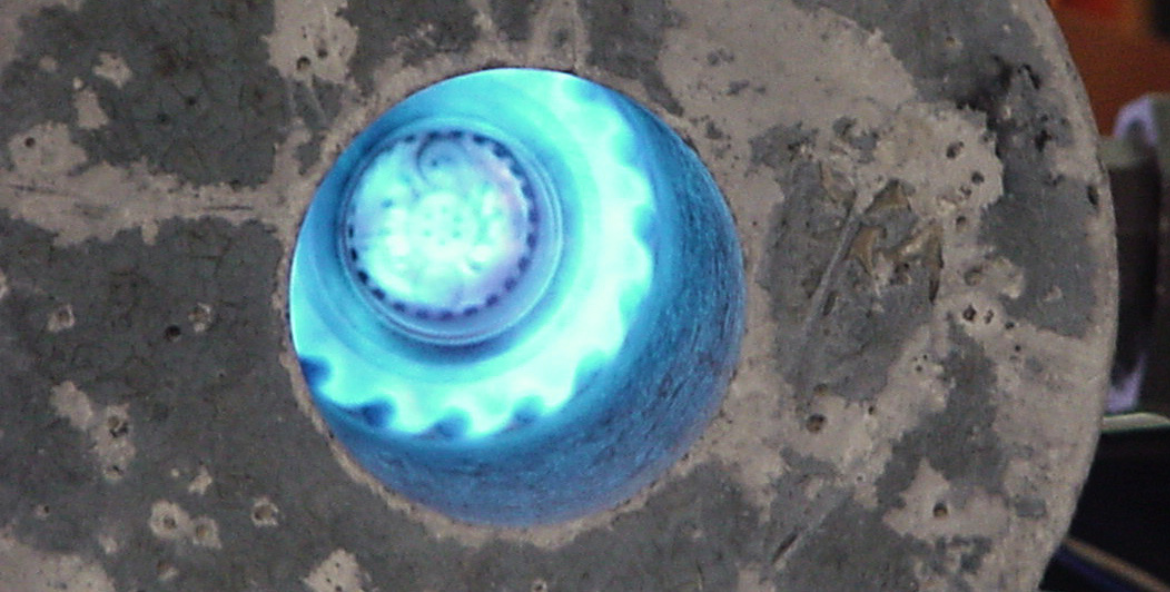

This 2 MMBTUH Heater Box generates the hot air needed to feed ETTER Web Scrubbers for high speed web printing of the cardboard used for a large beer manufacturer’s case boxes. ETTER provided an integrated solution of the Heater Box, Burner, Valve Trains and Controls along with the Web Drying Nozzles that are not pictured to the left. The Heater Box was fully tested as part of our QC Process.

#2: Heat Source for Print Drying

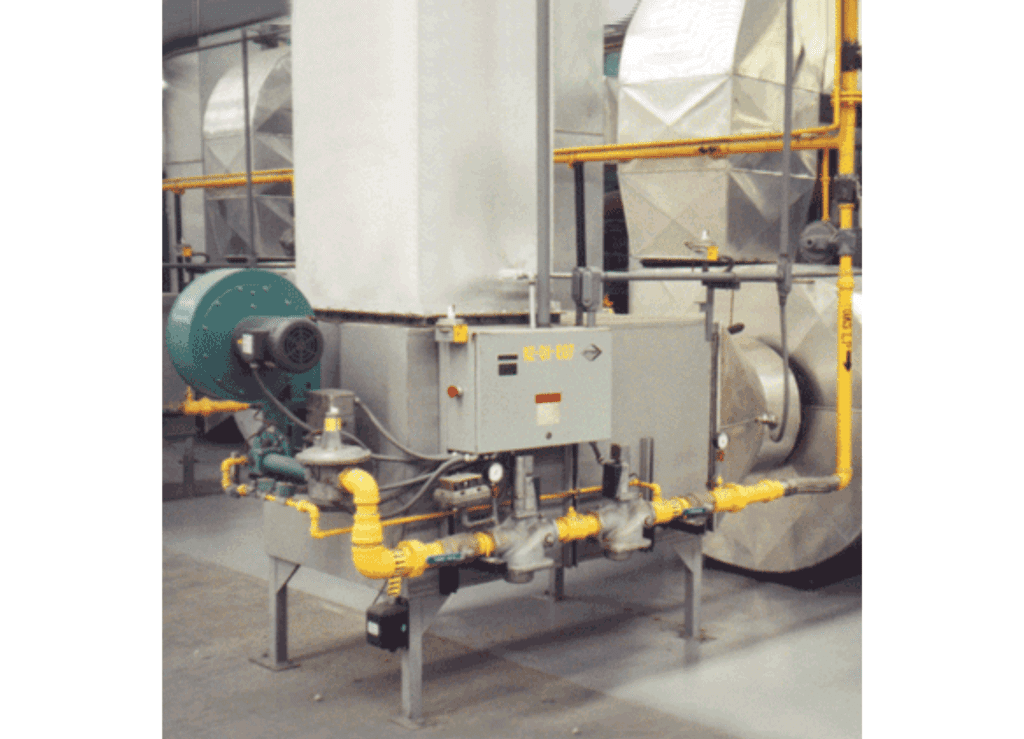

ETTER provided 1.5 MMBTUH Heater Box as the heat source for drying web based multi-station printing at this facility. Our scope included a skid mounted system for ease of installation, the insulated Heater Box, outlet high temperature supply fan, complete packaged burner system with main gas and pilot gas valve trains, and Burner Management control panel. This unit was test fired for a Factory Acceptance Test (FAT) prior to final QC and Shipment assuring an easy start up.

#3: Coating Line Heat Sources

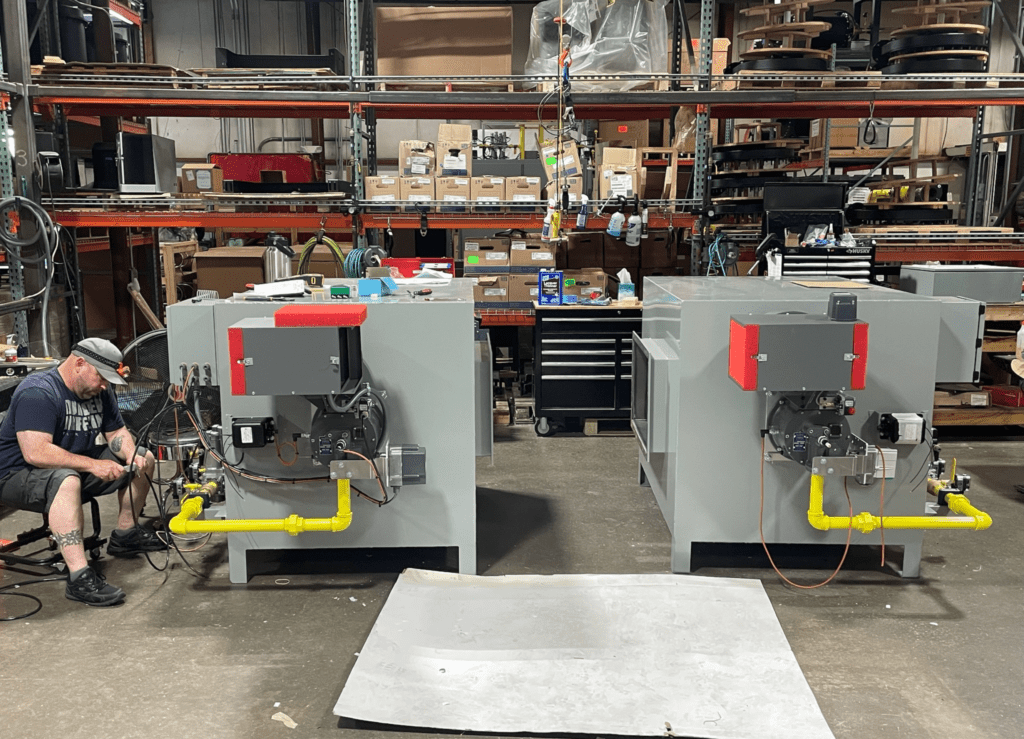

ETTER Engineering has supplied two complete Heater Box upgrades to an existing Coating Line for an industrial site. The original Heater Box was 1970s vintage. The new Heater Box complies with current NFPA 86, 2023 Edition. The combustion system includes Maxon Burner, SIEMENS Valve Train, and LME71 Flame Safeguard, Pressure Switches, LFL Monitor, and combination Temperature Controller and Hi-Limit Safety. The Heater Box was assembled and fully tested prior at ETTER’s facility prior to installation at the Customer’s site.

#4: Outdoor Heater Box System for Fabricating Specialized Insulation

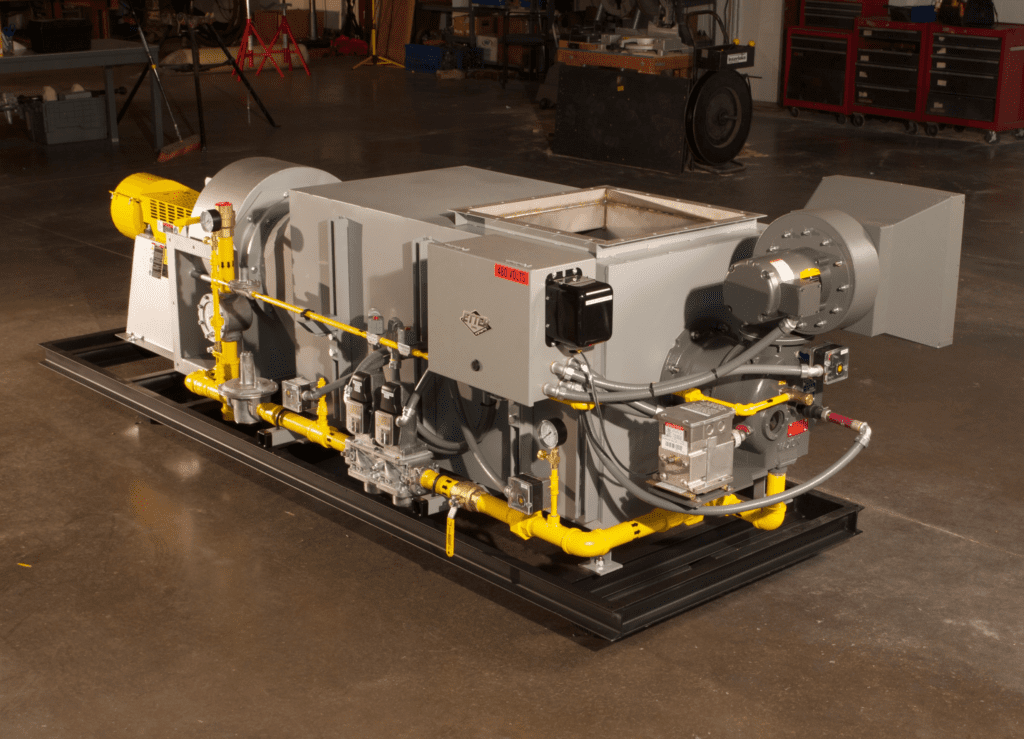

This is truly a Custom “one of a kind” system designed specifically suited for our client’s needs. One of a kind, but we ended up making them three of these units. Their manufacturing process for their specialized industrial insulation consumes a high volume of 550 F air source that we provided to their oven. The package burner provided 3.5 MMBTUH of heat, complete with valve trains, supply fans, burner, heater box and controls. This outdoor system provided them the necessary industrial heat for their production lines while not consuming indoor footprint of floor space.

Custom Packaged Burner Systems: Solutions for Optimal Performance and Efficiency

ETTER Engineering’s packaged burner systems are built to meet all required codes and incorporate the latest technology for optimal performance. Perfect for plants or institutions looking to upgrade older equipment, our systems also offer a streamlined solution for OEMs in the process heating industry, allowing them to focus on their product while we handle the combustion system. Working directly with numerous OEMs, we act as an extension of their team, saving time, money, and valuable resources with a single purchase order.

Our burner systems are designed to meet your specific process needs, with capacities ranging from 50,000 to 200 million BTUH. Choose from our standard systems or let us customize a solution to fit your company’s unique requirements. With decades of expertise in process heating and combustion, ETTER Engineering is the ideal partner to handle your critical needs—we understand combustion and are committed to delivering the right solution for you.

Suitable for All Processes, Including

- Printing and Coating

- Food Processing

- Pharmaceuticals

- Paper & Plastic

- Drying Systems

- Textiles

- Metal Finishing

Burner Systems May Include

- Pre-piped Valve Train

- Wiring to Junction Box

- Support Framing

- Drawings and Documentation

- Factory Testing

MAKING INDUSTRIAL SYSTEMS

Run smoother, safer,

and better

Our team of expert engineers are ready to provide the precision and reliability your operations deserve. Contact us today for a quote on your next project.