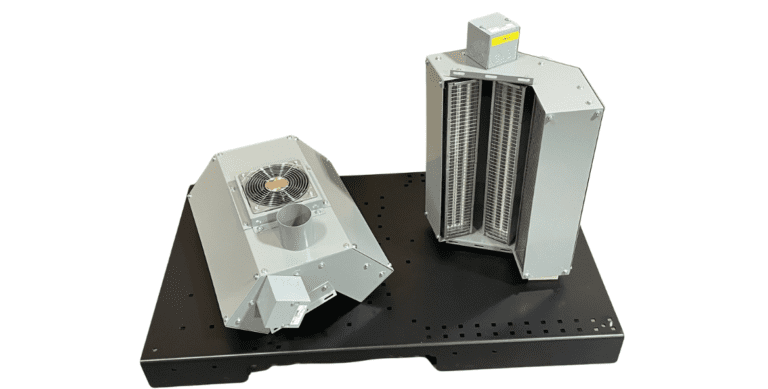

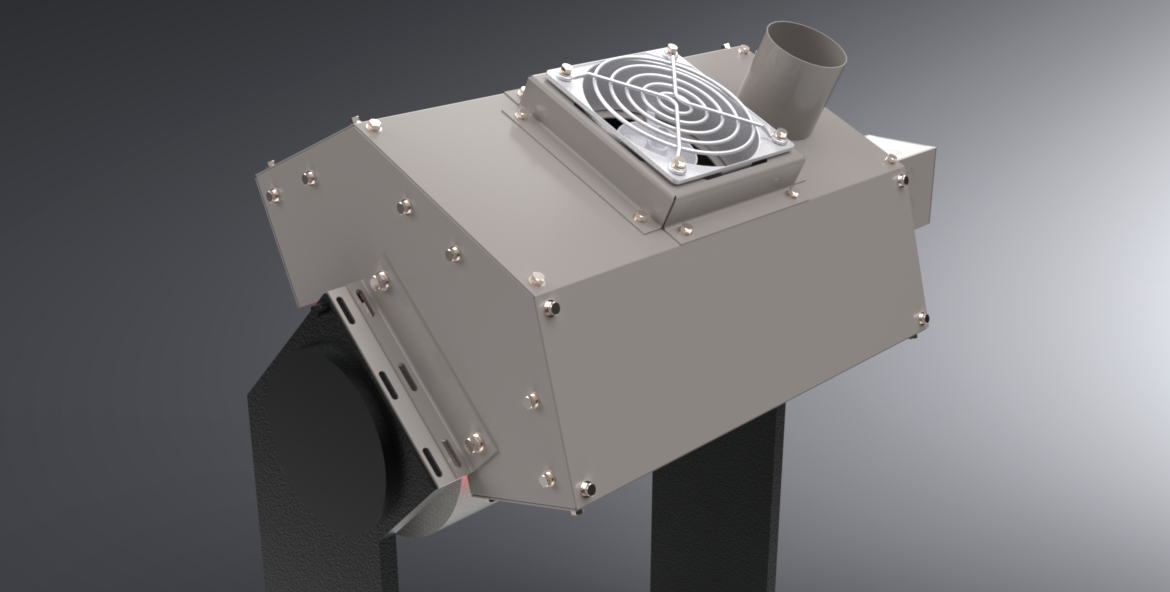

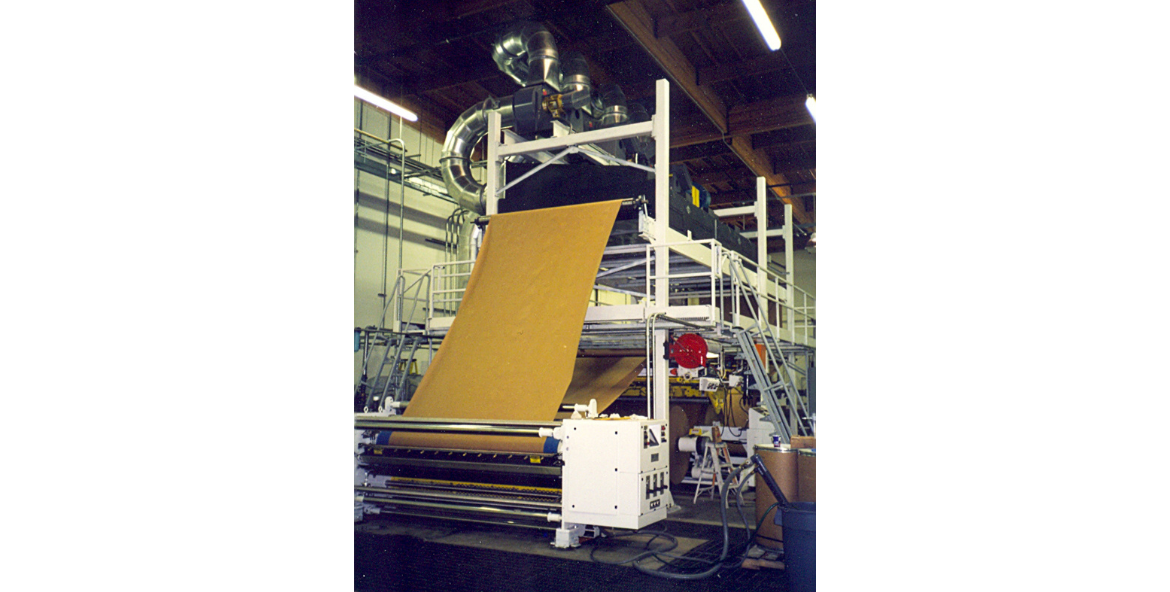

ETTER Engineering’s proprietary high velocity air drying systems are designed to offer unmatched drying efficiency with our unique twin vortex technology. Whether you’re upgrading existing presses or equipping new presses, our systems provide superior performance in both water and solvent-based inks and coatings. Custom designed to meet your specific application requirements, our systems deliver higher line speeds, improved print quality, and reduced maintenance.

- Higher Line Speeds: Achieve over 100% increase in line speeds.

- Better Quality: Enhanced drying for printing on paper, film, and foils.

- Reduced Maintenance: Non-clogging nozzle design for fewer maintenance needs.

- Solvent to Water Conversion: Ideal for making the switch from solvent to water-based inks.

Customized for Your Project's Needs

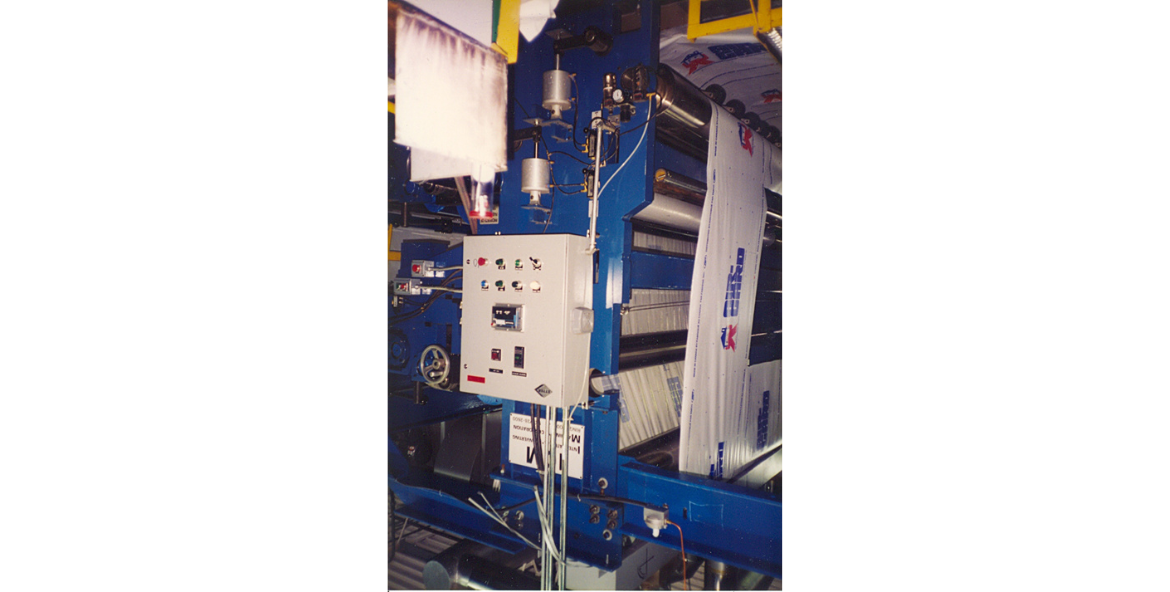

At ETTER Engineering, we specialize in custom-designed high velocity air drying systems tailored to your specific application. Our systems are perfect for a variety of presses and coaters, and they can be integrated seamlessly into your existing setup or supplied as original equipment for new presses.

- Flexo and Gravure Presses

- Stack and C.I. Presses

- In-line Presses

- Coaters and Multi-Station Coaters

- Infrared Drying Capabilities

- Web Widths from 6” to 150”

- Overhead Tunnel Dryers

Upgrade Your Presses with ETTER Engineering

Our high velocity air drying systems improve efficiency and quality, whether you’re working with water-based or solvent-based inks. Let ETTER Engineering design the perfect solution for your unique needs, delivering superior results with minimal downtime and maintenance.

Contact us today to learn how ETTER’s Web Drying Systems can enhance your production process.

Additional Products:

MAKING INDUSTRIAL SYSTEMS

Run smoother, safer,

and better

Our team of expert engineers are ready to provide the precision and reliability your operations deserve. Contact us today for a quote on your next project.