Built for Your Needs

Your Partner in Combustion Engineering and Solutions

Since 1940, ETTER Engineering has delivered innovative combustion solutions, combining expertise, advanced technology, and exceptional service.

From high-quality parts to custom-engineered systems, we prioritize safety, reliability, and efficiency to help industrial and commercial clients optimize operations and reduce energy consumption. Our mission is to empower industries with solutions that drive performance today and sustainability for tomorrow.

1

Years in Business

1

Happy Customers

1

Projects Done

1

Pro Employees

Expert Combustion Solutions

Massachusetts Variances

Calibration and Pyrometry

Combustion Safety Audits

Combustion Services

Precision-Engineered Systems for Safer, Smarter Operations

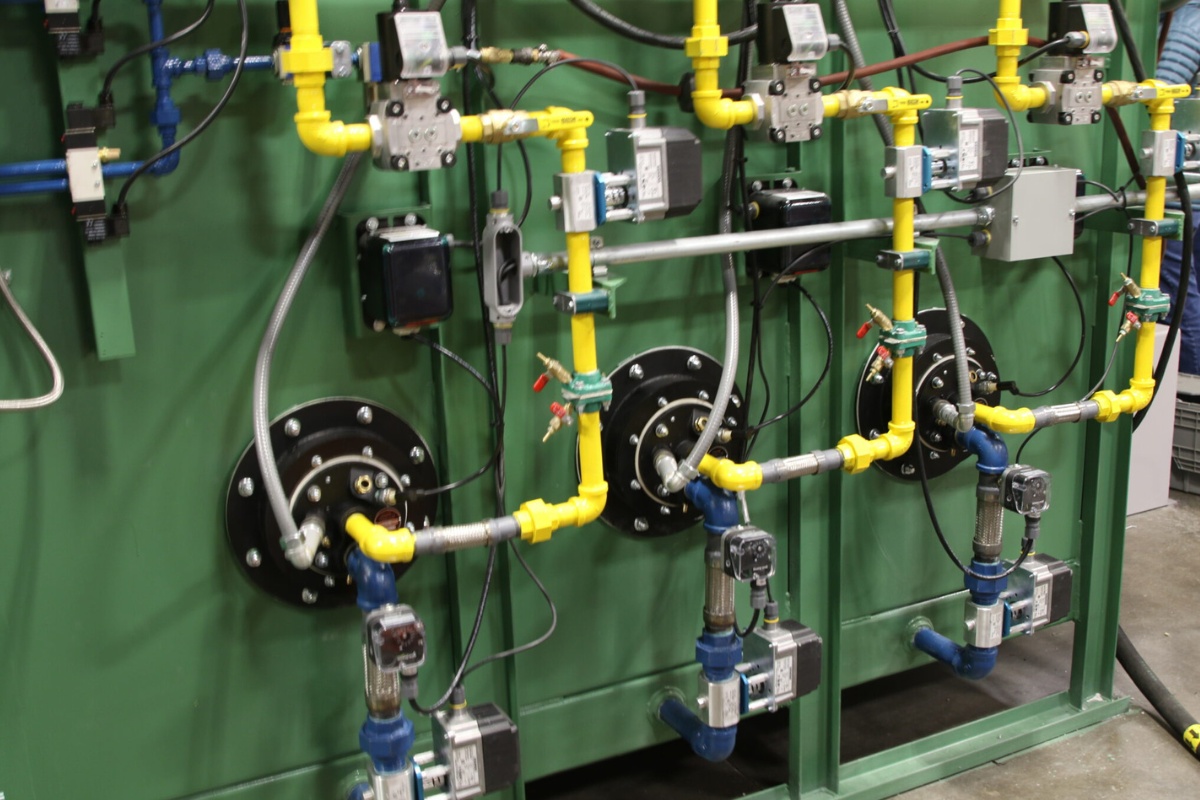

BoosterWorx

UL-Listed, hermetically-sealed natural gas boosters engineered to meet the demands of modern applications. We also offer a full suite of accessories to ensure smooth, efficient, and cost-effective installation.

IntelliWorx

Intelligent monitoring and control solutions that deliver real-time data, increase energy efficiency, and enhance system performance—keeping operations running smoothly and predictably.

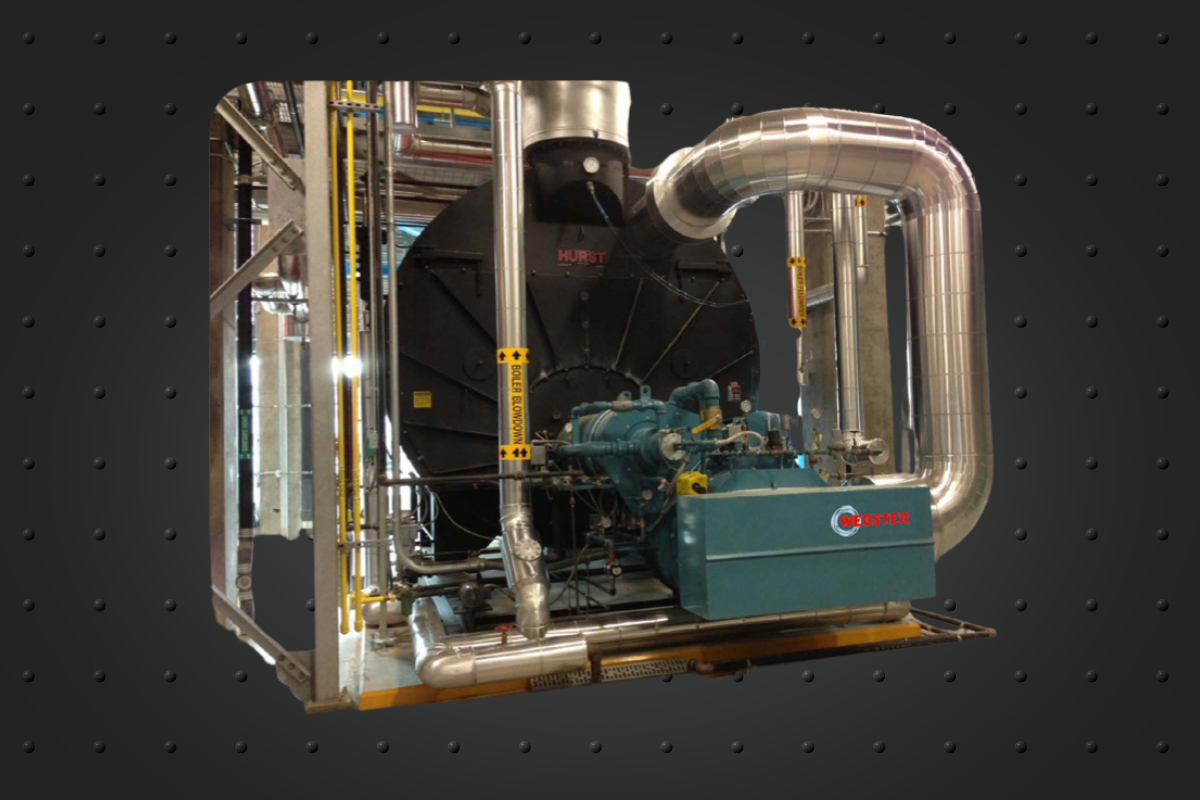

BurnerWorx

Complete packaged burner systems designed with the latest combustion technology and built to meet all applicable codes. Dependable, high-efficiency performance in demanding environments.

SafetyWorx

A full line of gas safety systems designed for commercial and institutional settings. SafetyWorx products ensure secure monitoring and control of gas flow for optimal safety and compliance.

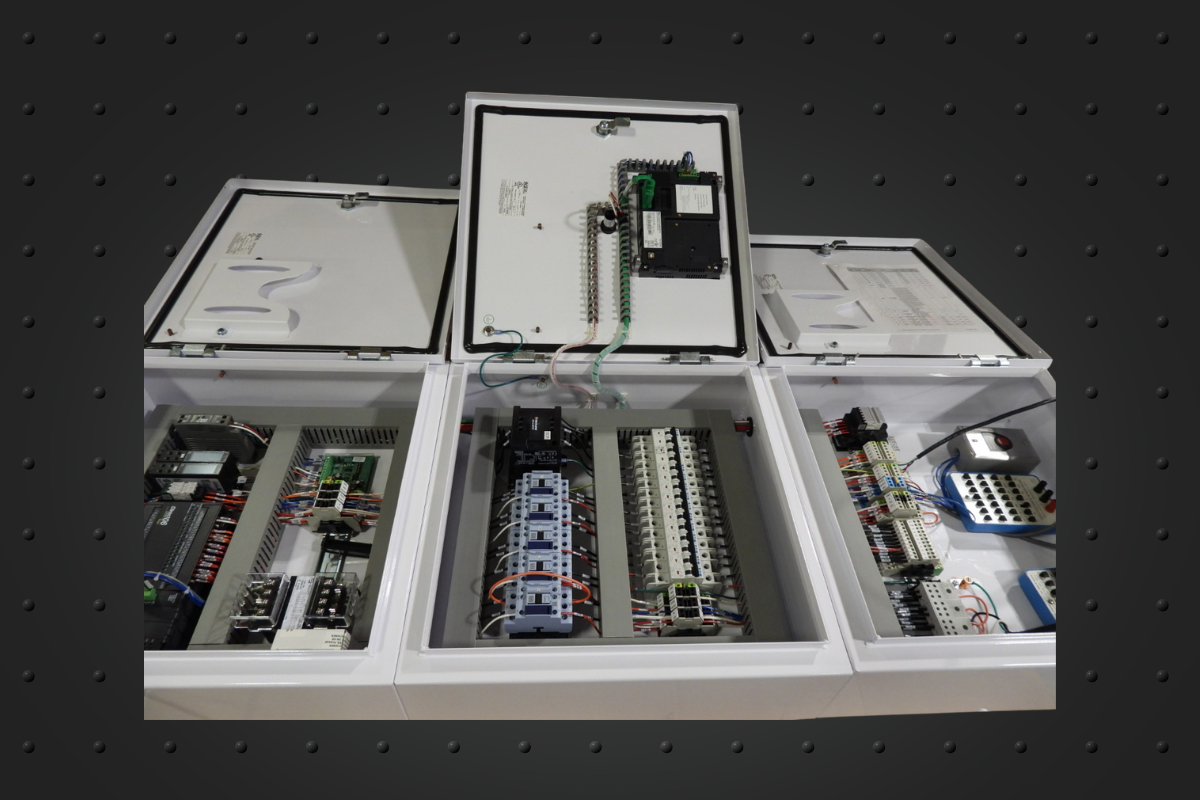

ControlWorx

From custom UL-508A control panels to the advanced SBCP 1000 burner control system, ControlWorx delivers reliable, code-compliant solutions engineered for safety, precision, and performance.

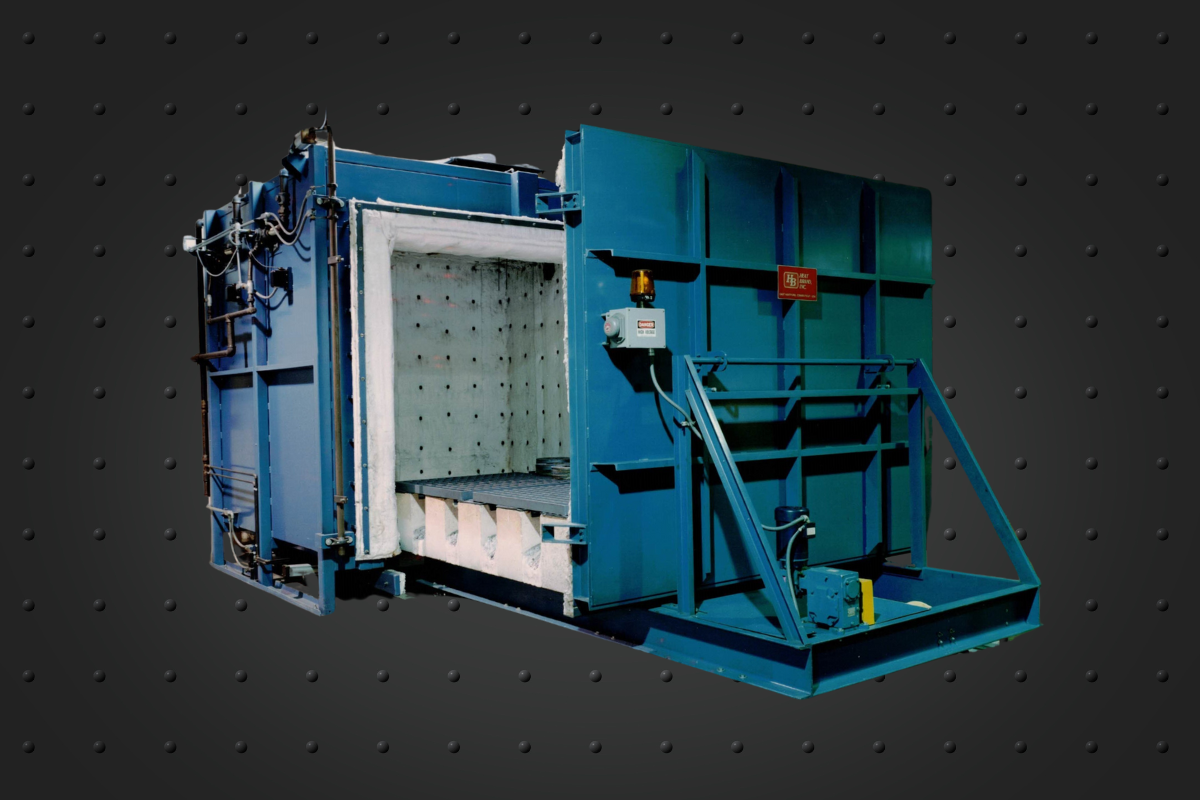

FurnaceWorx

Custom-engineered industrial heaters and furnaces for processes such as powder coating, curing, and drying. Each system ships ready to install and is designed for quick startup and consistent results.

BoilerWorx

Engineered for durability and performance, BoilerWorx offers UL-Listed natural gas boosters tailored specifically for boiler applications. Built for safety, efficiency, and long-term reliability.

Methane Abatement System

Where Expertise Fuels Innovation

Testimonials

“I wanted to take a moment to let you know that I am now back to full operation. I really appreciate your help in getting me to this point. You accommodated us as we needed and I am very happy with the service we received. Again, thank you for your top notch service”

Jim Willard

Metal Works, Inc.

“Switching from expensive, dirty oil to clean, efficient natural gas will allow us to realize huge cost savings. ETTER Engineering helped my business and they were a pleasure to work with – knowledgeable, responsive and extremely professional!”

Peter Andolino

A&M Bronx Baking

“There’s a ton of combustion going on [here], and I trust ETTER Engineering 100% to get the job done right, saving me time, money, and providing me with peace of mind that my equipment is running at peak efficiency.”

Frank Timmeny

Director of Manufacturing, Bridgeport Fittings

“ETTER’s customer service, prompt response, and competitive pricing helped ensure Podojil Builders was able to provide a quality product to the owner. Any future needs I encounter for booster systems will be handled by the team at ETTER Engineering”

Paul Podojil

Podijil Builders

I want everyone at ETTER to know the great service we have received from Jamie and Laldeo. The next time we need service the only call I would make is to ETTER.

Kevin Wash

Lead Roaster, Red Barn

Innovation

“Logic will get you from A to B. Imagination will take you everywhere.”

Latest News

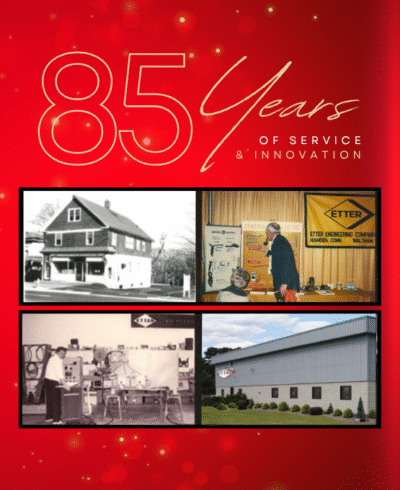

Celebrating 85 Years of Service and Innovation at ETTER Engineering!

Celebrating 85 Years of Service and Innovation at ETTER Engineering!

Choosing the Right Energy Efficiency Partner for Your Next Project

Choosing the Right Energy Efficiency Partner for Your Next Project

Advancing Methane Mitigation: Insights from the 2024 Methane Mitigation Summit

Advancing Methane Mitigation: Insights from the 2024 Methane Mitigation Summit

ETTER Engineering’s CMAS V2 Unit Sets New Standard for Methane Emission Reduction in Oil and Gas Fields

ETTER Engineering’s CMAS V2 Unit Sets New Standard for Methane Emission Reduction in Oil and Gas Fields

ETTER Engineering’s Contribution to the Peekskill State Armory Upgrade

ETTER Engineering’s Contribution to the Peekskill State Armory Upgrade

ETTER FAQs

We provide a comprehensive range of specialized services designed to keep your operations safe, efficient, and compliant—including combustion repairs, service audits, Massachusetts Variance support, and expert calibration and pyrometry services.

ETTER’s products are built and shipped from our Bristol, CT factory and main office. We take great pride in our products, utilizing local and USA-made components to the maximum extent possible. ETTER supports and services all the products we build, focusing on the ultimate safety of operators and the performance of the equipment.

ETTER serves a wide range of industries, including:

Manufacturing

Food and Beverage

Pharmaceuticals

Glass and Heat Treating

Finishing Equipment

Commercial HVAC

Wastewater Treatment

Printing and Web Drying

Aerospace

Utility

Foundry & Casting

Automotive

Agricultural

Baking and Curing

ETTER Engineering is a third-generation, family-owned industrial combustion company. Our team of 37 professionals—including fabricators, engineers, designers, service technicians, and control specialists—enables us to manage both small and large projects from concept to commissioning. We specialize in a wide range of products, from custom combustion systems to gas booster systems, as well as UL-508A control systems, to name a few.

Most projects at ETTER have a 6 to 12-week life cycle. However, custom, larger projects may take over a year due to factors such as scale, complexity, the approval process, and the manufacturing process.

Yes, this is where ETTER shines. Our in-house talent and expertise allow us to solve even your most challenging projects. We’ve designed one-off systems for NASA and created prototype systems for customers in need of a trusted combustion partner.

Our “daughter company,” Finishing Equipment Group, expands our offerings with TITAN Catalytic Infra-Red Ovens and NIKO Conveyors Material Handling Systems.